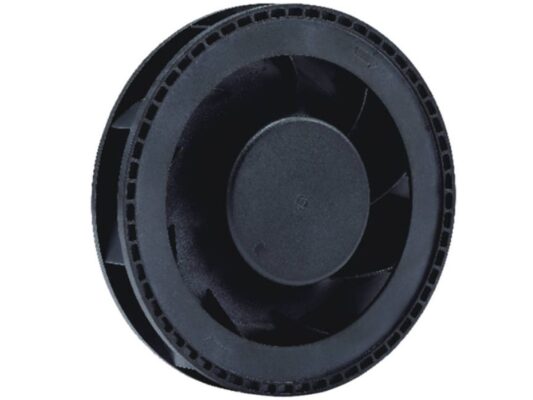

100x25mm Brushless DC Fan Backward Curved

Taming Heat in Small Spaces: A Comprehensive Analysis of the 100x25mm Backward-Curved Brushless DC fan

In the fast-moving world of industrial machines and electronic devices, the ongoing push for more compact, powerful, and efficient designs introduces a major challenge: heat dissipation. As components become more densely packed, the need for advanced cooling systems that are not only powerful but also small, adaptable, and incredibly dependable becomes crucial.

The 100x25mm Backward Curved Brushless DC fan arrives as a formidable answer, representing a pinnacle of modern engineering that offers a potent, versatile cooling capacity in a surprisingly compact form. This Brushless DC fan is far more than a simple component; it operates as a complete thermal management system, delivering unmatched flexibility with its multi-voltage operation, a wide array of speed settings, and a construction engineered for extraordinary durability.

The Aerodynamic Superiority of the Backward-Curved Impeller

The secret to this Brushless DC fan's exceptional performance is found within its sophisticated backward-curved impeller architecture. Unlike axial fans that push air along the motor's axis or forward-curved blowers, this design employs blades that curve away from the direction of rotation. This distinct aerodynamic profile confers several critical benefits, positioning it as the top choice for high-impedance applications.

First, backward-curved blowers are known for their outstanding static efficiency. This means they are incredibly effective at converting motor energy into air pressure. This pressure-building capability is vital for overcoming system resistance, such as forcing air through dense heatsink arrays, complex ducting, tightly packed server hardware, or high-efficiency particulate air (HEPA) filters. While other fans might suffer a dramatic loss of airflow against such obstacles, this Brushless DC fan maintains strong output, guaranteeing that critical parts receive the necessary cooling.

Second, this design has a non-overloading power curve, which is an inherent safety mechanism. As system resistance falls and airflow consequently increases, the power consumption of the motor levels off and then decreases. This attribute prevents the motor from drawing too much current and overloading, even when operating at its maximum airflow point (where static pressure is zero). This self-regulating quality protects the motor from damage and boosts the overall reliability and safety of the system it is integrated into.

Unmatched Versatility: Multi-Voltage and Multi-Speed Functionality

Perhaps the most remarkable feature of this Brushless DC fan is its phenomenal operational adaptability. It is built to function optimally across different DC voltages while providing a broad spectrum of speed configurations. This allows system designers to choose the exact performance level required for any given situation. This flexibility can remove the need to source different blower models for various projects, thus simplifying supply chain management and design processes.

12V DC Operation: When powered by a 12V supply, this Brushless DC fan delivers three separate performance levels, balancing airflow, energy consumption, and sound output:

Low Speed (L): Ideal for steady, quiet operation, this setting runs at 2000 RPM. It consumes just 1.44W, produces 30.8 CFM (52.33 M³/hr) of airflow, and generates 5.61 mm-H₂O of static pressure. With a sound level of only 32 dBA, it is well-suited for office equipment or noise-sensitive medical devices.

Medium Speed (M): Offering a boost in capability, the medium setting operates at 3000 RPM. Airflow increases to 38.5 CFM (65.41 M³/hr) with 8.36 mm-H₂O of static pressure. This mode presents a balanced middle ground for applications needing enhanced cooling without a major rise in noise (43 dBA).

High Speed (H): For challenging cooling tasks, the high mode spins at 4000 RPM. It pushes a powerful 53.9 CFM (91.58 M³/hr) and creates a substantial static pressure of 16.61 mm-H₂O, making it capable of managing significant thermal loads. This peak 12V performance is achieved at a moderate 50 dBA.

24V DC Operation: Shifting to a 24V power source unlocks the fan's greater efficiency, matching the speed tiers of the 12V mode but with different electrical figures:

Low (L) & Medium (M) Speeds: The performance metrics for airflow, velocity, static pressure, and noise at the 2000 RPM and 3000 RPM settings are identical to the 12V operation. The Brushless DC fan, however, accomplishes this with superior electrical efficiency, drawing only 0.07A and 0.10A respectively.

High Speed (H): At the 24V high setting, this Brushless DC fan replicates the 12V high-speed performance of 4000 RPM, 53.9 CFM, and 16.61 mm-H₂O, providing robust cooling for thermally intensive setups.

Ultra-High Performance Mode (16.5 V DC - "U"): For uses requiring the absolute maximum performance from this form factor, the fan includes a special ultra-high-speed mode specified at 16.5V.

Ultra Speed (U): This setting drives the fan to an exceptional 4800 RPM. It produces a formidable airflow of 63.8 CFM (108.40 M³/hr) and a peak static pressure of 20.30 mm-H₂O. This configuration is engineered to handle the most severe thermal conditions in the most compact electronics, ensuring system stability under heavy loads.

This impressive variety of operational modes makes this single Brushless DC fan model a complete solution for engineers, offering performance profiles suited for everything from silent, gentle airflow to aggressive, high-pressure spot cooling.

Designed for Longevity: Resilient Materials and Construction

A Brushless DC fan's performance is incomplete without dependability. This fan has been carefully assembled from premium materials to guarantee an exceptionally long and maintenance-free operational life.

Bearing System: At its core are high-precision ball bearings. Offering significant advantages over conventional sleeve bearings, ball bearings produce less friction, have greater efficiency, and a much longer lifespan, rated for an anticipated 50,000 service hours. They are also less susceptible to temperature changes and allow the fan to be mounted in any orientation without affecting its performance or durability.

Impeller and Housing: The impeller and its mounting base are created via injection molding with a high-temperature-resistant Polyamide engineering plastic. This advanced polymer is selected for its remarkable strength, stiffness, and thermal stability, ensuring the impeller blades retain their exact aerodynamic shape even when operating continuously in environments reaching 70°C (158°F).

Motor Base: The motor of the Brushless DC fan is mounted to a die-cast ADC12 aluminum base. This part not only provides a rigid, vibration-dampening structure but also acts as an effective heat sink, pulling thermal energy away from the motor's windings to promote cool, stable, and efficient operation.

The fan's electronic components are equally robust, featuring Class B insulation and an insulation resistance of 10MΩ/500VDC, which protects against electrical faults and ensures operational safety across its wide -10°C to +70°C operating temperature range.

Integration and Applications

The combination of a small 100x25mm frame, powerful performance, and operational versatility makes this Brushless DC fan an excellent choice for a broad range of uses:

It is an optimal choice for blade servers, network switches, routers, and other rack-mounted equipment where high-density electronics produce immense heat in confined spaces. Its quiet operation at lower speeds and high reliability make it fitting for diagnostic machinery, analytical tools, and medical devices where both performance and patient comfort are paramount. It is perfect for cooling PLCs, motor drives, and control cabinets on factory floors, where dependability in harsh environments is critical. The high static pressure is ideal for pushing air through multi-stage filters in air purifiers or for use in localized ventilation systems. It also efficiently dissipates heat from high-power LEDs and display drivers, preventing performance degradation and extending product life.

Integration is simplified by the clear mechanical diagram, which provides precise dimensions and marks the three M4 brass nut mounting points for a secure and straightforward installation.

In conclusion, the 100x25mm Brushless DC fan is a shining example of the possibilities in modern thermal management. It is a compact dynamo that provides an unparalleled fusion of performance, adaptability, and durability. By offering a wide operational scope across multiple voltages and speeds, and by being built upon a foundation of quality materials and superior engineering, this Brush-less DC fan gives designers and engineers the ultimate tool to solve complex cooling challenges, helping their products run cooler, last longer, and perform better.